This post marks the destructive denouement of VIA's unprecedented buffer-car era. Trackside Treasure's comprehensive and complete coverage of the nearly exactly seven-month span, published in six previous posts published since October, 2022, and one subsequent:

- Breaking News! Buffer Cars Added to VIA Trains - October 13, 2022

- Testing VIA's HEP Fleet - November 7, 2022

- Buffer Cars in the News - November 10, 2022

- The Report That Hatched Buffer Cars - November 30, 2022

- HEP Buffer Car Corridor Consists - February 18, 2023

- Testing VIA's HEP Fleet - The Results Are In! - April 13, 2023

- Death and Disposition - July 10, 2024

THE FINAL REPORT

VIA Rail Canada provided Transport Canada with a final report dated March 31, 2023, pursuant to the fifth paragraph of the October, 2022 ministerial order. The report was the last in a series, all provided by the HATCH engineering firm utilized by VIA. An April 12 Project Memorandum from HATCH to VIA was part of the firm's mandate to provide guidance to VIA on how to address findings of the Heritage Program inspection campaign encompassing the entire Head-End Power (HEP) fleet.

In its January 31, 2023 prior report to VIA as part of the ministerial order requirements, HATCH had suggested continued use of buffer cars until the testing program was complete. Compression testing performed by that report date had showed that the cars complied with original design standard for the HEP cars AAR S-034:1945. Carbody degradation had not degraded the cars' buff strength. These successful test results ruled out the need to reassess and repeat a crash analysis.

Compression testing was performed at the National Research Council (NRC) Automotive and Surface Transportation Research Squeeze and Tension Frame Facility in Ottawa. The testing methodology was undertaken by professional experienced staff from HATCH and NRC, to identify conditions such as cracks and permanent deformations which could be initiated or propagated as a result of the test. Waterton Park received a PASS as a result of the testing. Coach 8138 and sleeper Chateau Richelieu had significant reserve capacity noted during testing before yielding commenced, though they also received a PASS.

Accompanying the HATCH Project Memorandum was the 76-page Final Report on Carbody Structural Assessment of the HEP fleet. I should note that only through VIA's Access To information (ATI) legislative requirements was this report obtained. A precis of the report is included below, [with editorial comments in square brackets].

Sections contained in the report:

- Tear-down Inspection Planning, Car Preparation, Tear-down Inspection Procedure, Inspection Results and Analysis.

- Compression Load Test Instrumentation, Compression Test Procedure, and Results & Analysis.

- Overall Conclusions and Recommendations.

- Work-in-Progress.

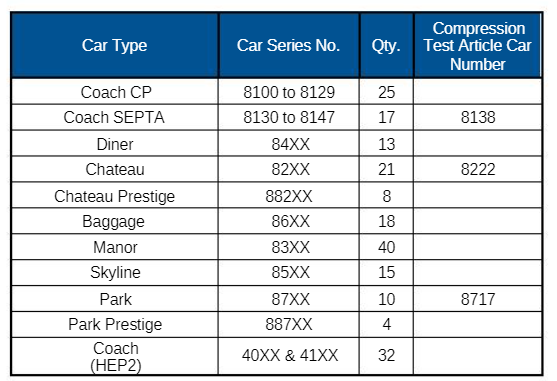

As of the report date of March 31, 2023 tear-down inspections were essentially complete on eight of the planned 10 cars deemed representative of VIA's 203-car HEP fleet. Further compression testing of Waterton Park was still scheduled for April 12, 2023. No further tear-down inspections were deemed necessary. As of the report date, HATCH already recommended removal of buffer cars protecting standard configuration (non-dome) cars. Removal of buffer cars protecting the dome [Park] cars on the Prince Rupert and Canadian western routes was to be reviewed after the scheduled April 12 tests. In fact, buffer cars were not removed by VIA until May 18, 2023.

Paragraph 6 of the ministerial order stipulated compression testing of at least one fully-repaired HEP car. This testing was intended to validate the repair methodology, and was based on a premise that only repaired cars would be in compliance with the AAR standard. Since a failure condition was not found during compression testing, the testing of a repaired car would not demonstrate the effects of such repair. If a failure was found after testing Waterton Park, the repair of Park cars was to be addressed separately.

Eight cars were selected for tear-down inspections, exceeding the recommended number of four cars. Cars selected had to:

- have had no previous structural repairs.

- have a representative level of deterioration in the eight known conditions found during VIA's STR inspections conducted, or during the Heritage Program.

- represent variations in primary underframe structure configuration (i.e. the testing of dome cars).

- be representative of various service conditions and route service environmental exposure.

- have car history considered.

Compression Tests:

- Chateau Richelieu (28,000): 1st load test then teardown, potential deterioration from toilet modules.

- 8138 (52,000): 2nd load test then teardown, riveted side sill connection

- Waterton Park (40,000): 3rd load test, unique centre sill transition at dome section.

Tear-down Inspections:

- 6208 (4,621): unique configuration

- Chateau Rouville (40,567): potential deterioration from toilet modules

- 4006 (98,756): [nil]

- 8618 (97,536): unique underframe structure due to doors

- Stuart Manor (91,030): potential deterioration from toilet modules

- Alexandra (74,000): potential deterioration from kitchen area

- Strathcona Park (60,191): unique centre sill transition at dome section

- 8505 (31,000): unique centre sill transition at dome section

CAR PREPARATION

All cars selected for testing received full strip-down of interior and underframe to gain full access to hidden structural elements and their connections. After strip-down, materials obstructing inspection of car shell i.e. insulation, primer and paint, shimming, adhesive residue, corrosion product and dirt were removed. For compression test cars, locations to receive strain gauges were cleaned to bright metal to properly attach gauges.

Such destructive cutting rendered cars unuseable for structural testing. Therefore, compression-tested cars received a partial tear-down inspection after testing, as required.

TEAR-DOWN INSPECTIONS

Inspections were performed by HATCH's qualified inspectors using three methods:

1. Visual

2. Liquid penetrant crack indicator (PT)

3. Ultrasonic measurement (UT)

The industry contractor [CAD, though not mentioned by name in the report] was provided with itemized procedures accompanied by labelled photo-diagrams. After inspections, results of all three methods were combined and presented as photo-diagram record sheets of inspections showing thickness measurements, to give an overall assessment of the cars' condition.

The eight conditions already known to VIA prior to inspections were:

1. Side sill cracks and defects (found in all 11 cars).

2. Draft sill top flange to floor part welds, cracks (11 cars).

3. Partition post corrosion.

4. Vestibule sub-floor corrosion.

5. Top centre sill transition zone cracks.

6. Centre sill transition zone weld cracks.

7. Bottom centre sill transition zone.

8. Body bolster corrosion at floor pans (11 cars)

Additional primary load-path elements inspected at tear-down were:

9. Draft sill flanges, webs, gussets and draft gear pockets.

10. Bolster top and bottom plates, flanges and gussets.

11. Bolster connections to side sill including internal plates and attachments.

12. Bolster centre plates.

13. Centre sill to bolster transition structure, flanges, webs and connections.

14. Collision post steel members.

15. Jacking pads and connections.

16. Cross bearers and connections.

17. Centre sill structure, transitions and major transition (Park car)

18. Sidewall to side sill structure and connections.

19. Condition of welds and attachments for all of the above.

Report tables showed the conditions that were present in each car, though some conditions were not applicable to all cars due to car type and design. According to these tables:

- 8618 had 17 conditions present

- sleepers had 11 conditions present

- 6208 had 14

- Alexandra had 12

- 8505 had 10

- Park cars had 13

- 4006 had 14.

VISUAL AND PT INSPECTION RESULTS

Several findings were revealed by visual and liquid penetrant crack indicator testing:

- Welds were found cracked, corroded or with loss of thickness as was corrosion at connections (normally invisible).

- Carbon steel exposed to the environment had very little corrosion loss.

- Cars with water sources onboard had more significant corrosion.

- Overall, no notable deformations, loss of shape, nor sag was observed.

- 8138 will receive detailed tear-down having passed compression testing.

UT RESULTS

The loss of thickness noted at inspected points were also presented, in table form. The most notable, highest percentages of thickness loss were:

- Waterton Park - 50% at draft sill top flange.

- Chateau Rouville - 42% at draft sill top plate-interior.

- 4006 - 46% at bolster connection to side sill.

- 6208 - 31% at bolster connection to side sill.

- Alexandra - 59% at draft sill top flange.

- Stuart Manor - 43% at draft sill top flange.

- Strathcona Park - 38% at transition zone bottom flange.

OVERALL TEAR-DOWN RESULTS

The most notable observed deterioration was found at:

- Draft sills - top flange and top plate

- Bolsters - top plates, webs and connecting plates to side sill

- Transition zone - carbon steel plates and members.

COMPRESSION TESTING RESULTS

[This list of cars selected for compression testing confirms the identity of one previously-unconfirmed wrapped Park car delivered to the National Research Council facilities at the end of February. That is, after testing coach 8138 (tested January 2023) and Chateau Richelieu (tested December 2022), that it was Waterton Park/8717 that arrived at the end of February for testing of the unique dome [Park car] design. The other possible wrapped Park car taken to NRC could have been Strathcona Park, but as the report reveals, that unfortunate Park car was torn-down at CAD.]

At the NRC facility, compression tests comprised force applied in two ways, that is, two locations in the car's underframe where force would be directed in a train-to-train collision:

1. To line-of-draft (buff) stops in draft gear channel.

2. To end-sill anti-climb stops

Compression loads were applied at 100 kips/minute with stops at each five minutes, up to the standard of 800 kips. [Kips are a customary US unit of force, equalling 1,000 pounds-force.] Once the standard 800,000 pounds were applied (800 kips), compression testing continued until failure mode (geometric instability of the draft sill and centre sill) was reached. The compression test values were 885 kips for Chateau Richelieu and approximately 1,000 kips for 8138.

Chateau Richelieu's centre sill has been crippled:

Both cars passed the 800 kips line-of-draft test and 8138 passed the 500 kips end-sill test. Testing on 8138 did not proceed to failure mode. This was due to 8138's design redundancy which displayed a large margin above the standard and above the testing RAM's ultimate capacity.

SUMMARY OF FINDINGS AND CONCLUSIONS

The testing provided VIA with valuable findings to positively guide remaining efforts in the Heritage Program.

1. Tear-down inspections showed that some areas of carbody structure deterioration were NOT being captured by VIA's C630.002 Inspection Procedure [the "STR"]. Areas requiring attention included the following conditions in the cars' load-path: corrosion on bolster top plates, corrosion on bolster-to-side-sill connecting plates and draft will top plates in the vestibule area.

2. Deterioration found in tear-down inspections did not alter compression test results due to inherent HEP-car design redundancy. Compression testing excess capacity between elastic limit and global (ultimate) failure would guide VIA's repair to improve the fleet's structural connections. Load and strain readings suggest current structural repairs be extended to bolster connections, floor pans and draft sills inboard of the vestibule.

3. VIA still must conduct an engineering review to assess effects of deterioration and potential mitigations.

4. Observed hidden deterioration will continue until addressed by an ongoing repair program. The program will take some time to be implemented across the entire HEP fleet.

5. Compliance with the AAR standard directly mitigated the risk of train-to-train colllisions envisioned in HATCH's Technical Advice initial risk assessment dated October 17, 2022.

RECOMMENDATIONS

1. Since VIA's HEP fleet is currently compliant with the AAR standard, no further simulations are recommended or required.

2. Buffer cars other than those coupled to Park cars can be removed and HEP consists returned to original configuration.

3. Testing of repaired HEP cars was not necessary.

4. Conclusions from the report are only valid until the HEP fleet experiences changes in deterioration. VIA should enhance visual inspection requirements of their STR to include systematic monitoring of areas noted with cracks such as cross bearer connections, bolster connection and centre sill transition zone, including visually-accessible ring/plug welds. Cars with changes in crack sizes and number of cracks should be flagged for engineering evaluation or potential early repair. VIA should conduct an engineering assessment of deterioration noted in tear-downs and compression tests and use UT-mapped measurements of draft sills, bolsters and transition zone gussets to monitor changes in thickness loss until repairs are made.

5. Based on test findings, HATCH provided VIA with several technical recommendations for VIA's approach to the eight conditions that VIA shop forces were already monitoring.

WORK-IN-PROGRESS

As of the report date of March 31, 2023 three activities remained to finish the assessment (above-and-beyond ministerial order-mandated work but part of HATCH's mandate):

- 8138 tear-down - to gather additional inspection data on this coach that successfully passed the compression load test without permanent deformation.

- Waterton Park - compression load testing.

- 8505 - completion of tear-down testing.

EPILOGUE

Though I won't be corroborating the dates and data in question, I believe that the timespan between issuance of the Project Memorandum dated April 12, and the removal of buffer cars on May 18, was due to the completion and communication of the three work-in-progress tests to Transport Canada. A photo depicting a line of tested HEP cars, ostensibly heading for a Montreal-area scrap yard was briefly posted to social media before being speedily removed. However, a June 17 photo shows Alexandra, 6208, 8505, and Strathcona Park still there. Scrapping can apparently occur at CAD. Terry Allan kindly shared the following four photos, taken at CAD and conclusively showing all eight torn-down cars still there as of July 23, 2023 (below). Note the see-through appearance of the windowless carbodies, as well as the variable spacing with certain between-car components removed, especially both ends of the Business Class car:

Although the cars' names/numbers aren't visible, they're likely (left to right) Alexandra, 6208, 4006, Chateau Rouville, Stuart Manor, 8618, 8505 and Strathcona Park. Composite view (top photo).

So what was it all for? VIA shop forces will still be working with the 70 year-old cars' foibles, and instituting a more robust structural testing program.

The HEP fleet continues to roll into the future, although 5% smaller, as 11 of its cars were sacrificed to destructive testing. A new long-distance fleet cannot be procured immediately, therefore its arrival is still some years in the future. The Siemens Venture trainsets in the Corridor will replace the six consists' worth of HEP cars operating there now; perhaps the HEP cars will be the last of the three Corridor car fleets to be replaced. The two Renaissance Corridor consists are on borrowed time, and perhaps the LRC consists will be replaced next.

Passengers and pundits who decried the use of buffer cars were happy to see them removed. Some of those pundits are happy that nothing major was found, proclaiming it a nepotistic inside-job. Others, meanwhile, are unhappy that nothing was found, meaning a new long-distance fleet was not immediately required.

VIA Rail Canada and its engineering firm HATCH have done a credible job advocating for safety, providing what appears to this layman's eye as detailed and comprehensive reports.

The biggest loser in all of this, in my opinion, has been the dual concepts of accountability and transparency. From the initial discovery of cracks during the 2018 Rail GD diner rehabilitation which led to hurried inspection of in-service diners, through repatriation of HEP cars from across the VIA system to shops for inspection during the pandemic, through the resumption of services post-pandemic and now the buffer car era, VIA has not informed the public about potential safety risks that exist within its passenger car fleet.

In fact, passengers were left scratching their heads after receiving cryptic e-mails about curtailed baggage car access and Park car services, at the onset of the buffer car era. Most members of the travelling public would have had no idea about the implementation of buffer cars on the trains they were riding.

Your humble blogger beat the bushes, consulted trusted sources inside and outside VIA, made inquiries to relevant agencies, and correlated information from online media and industry reports, to piece together the facts regarding what was happening at VIA. Ultimately, I had to resort to two Access To Information requests, plus the results of an ATI request provided by another requestor, to see copies of the engineering reports and car information via VIA Rail Canada's own ATI process. VIA has not placed any restrictions on the sharing of the reports it provided.

The results have been shared in this series of posts. Let's hope that this fraught era of VIA's history is now behind us...like a buffer car.

Running extra...

The July-August issue of the Bytown Railway Society Branchline published my account up to February 2023. The six-page article includes my consist data and photographs as seen on Trackside Treasure.

Passenger Train Journal issue 2023-3 includes my artlcle on the final testing results as a Journal Spotlight item:

Then this happened. Shortly after publication, this Reddit supporter emerged:

6 comments:

Have the Prestige cars that had structural modifications such as larger windows been examined as the original cars were? One has to wonder if the larger window openings have lessened the cars' structural resistance to compression under sudden loading, such as in a collision or derailment.

It's nice that compression testing has demonstrated that these cars are still up to spec, yet these cars were already been sadly put to the test at Stewiacke and Hinton. Photographs and casualty counts demonstrated that most of the Budd stainless cars involved protected the occupants.

Steve Lucas

Thanks for your questiona and comments, Steve. I don't know what testing VIA did on the Prestige cars. I have heard that the moving of partitions in the Park cars may have led to some cracks or other changes in the roof sections. Needless to say, VIA sees Prestige Class as a revenue-generator, so will never allow any potential destruction of the fleet of Prestige Chateau and Park cars for structural integrity testing.

And yes, we have some resassurance that the HEP fleet is as safe as can be expected, especially bearing in mind its ages. The rest is now up to VIA. What to monitor, what to test, and maybe most importantly, when and with what to replace!

Eric

Would you be able to point to the direct report sources? You're writeup is fantastic but reading that actual reports would be very interesting.

As stated in the post, this is a precis of the original report as provided to Transport Canada.

Please sign comments with a name if possible.

Thanks,

Eric

Any chance you have the PDF version of the report?

Hi Mike,

I presented the report only as a precis, as it seemed to be the best way to present the most important information.

Eric

Post a Comment