Wednesday, November 30, 2022

The Report that Hatched Buffer Cars

Thursday, November 24, 2022

Invista Outbound Cars & Derailment

- SRLX Southern Rail Leasing

- PLCX General Electric Rail Services, formerly Pullman Car Leasing until 1986

- UTCX Union Tank Car Company

- INVX Invista

- ACFX General Electric Rail Services, formerly American Car & Foundry until 1997

Running extra...

- Nov. 27 Houghs/Disney (ABC)

- Nov. 29 Michael Buble (NBC)

- Nov. 30 Rockettes and Kelly Clarkson (NBC)

- Dec. 1 Dolly Parton (NBC)

- Dec. 8 CMA Christmas (ABC)

- Dec. 11 Tree-Lighting (CBS)

- Dec. 13 Mormon Tabernacle Choir (PBS)

- Dec. 20 Mariah Carey (CBS)

- Dec. 23 The Grove (CBS)

Wednesday, November 16, 2022

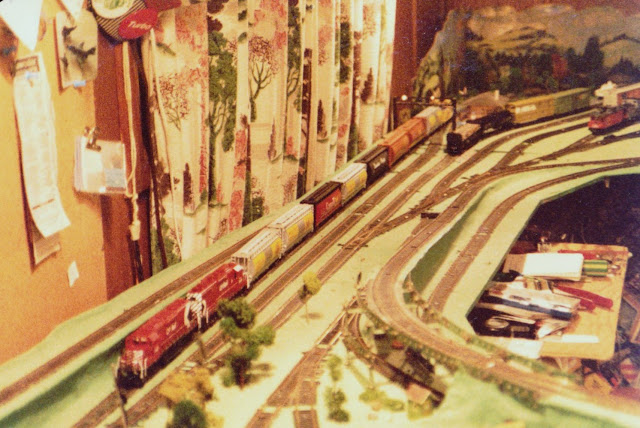

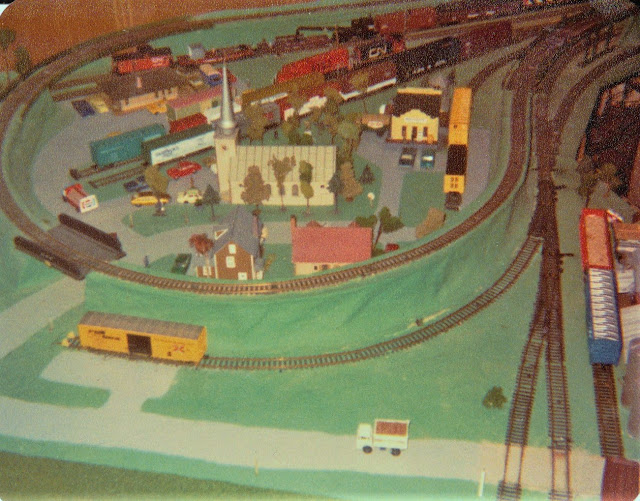

Manitoba Western Railway Layout, 1984

- Rivers Subdivision - most of the main line and Portage yard inside the right end of the dogbone

- Glenboro - the three-bridge embankment

- Carman - inside the left end of the dogbone

- Gladstone - addition under the beer bottles

- Winnipeg Terminals -final stub-ended yard addition

Thursday, November 10, 2022

Buffer Cars in the News

On November 9, reporter for the Quebec media newspaper network Le Soleil Gilles Gagne published this article. I was pleased to collaborate with Gilles. He was knowledgeable about the issue, and I was able to provide some additional information and context. This article is an important step forward in bringing the issue forward to a wider audience of not only rail enthusiasts, but passengers and taxpayers. Since the article is from the Le Soleil webpage with its limited number of available views, and originally published in French, I've translated and reproduced it here with permission. What follows is the published French version translated to English. Light edits that I made for clarity are in [brackets].

Monday, November 7, 2022

Testing VIA's HEP Fleet

Not to worry. Due to excellent sources and various online reports, Trackside Treasure can continue to publish updated information on just what's going on! Watch for updates to this post, which will not concentrate on cars in use, but will instead focus on testing and subsequent steps after the first three weeks of this disturbing debacle.

The Transport Canada Rail Safety ministerial order MO 22-06 requires testing of four cars, though it seems that one car of each type (baggage, coach, diner, Chateau, Manor, and dome) may be tested. These will likely be cars that are out of service for various reasons, including mechanical issues. The cars will be moved from Toronto or Montreal Maintenance Centres (TMC and MMC) to CAD Railway Industries in Lachine for stripping, thence sent to the National Research Council facility in Ottawa for strength testing, specifically their Squeeze and Tension Frame Facility. Testing is to be completed by January 31, 2023 per the order. There is speculation that cars already at CAD will be sent. But Strathcona Park and 4006(?) have been there for some time, the former with loose fixtures and equipment inside, and the latter with boarded-up windows. They don't appear to be going anywhere anytime soon! These were, in fact, never intended for stripping and testing, having been at CAD before the buffer-car issue arose.

NOVEMBER 6 UPDATE: Rumours have been flying over the past three days about an impending move of cars out of VIA maintenance centres for testing. Perhaps one source can't be deemed reliable, but triangulation and confirmation sure helps. Two shrink-wrapped cars arrived in Ottawa's Walkley Yard around 0630 today. The cars, a coach and a sleeper, appear to have underframe equipment removed.

The move from CAD to MMC took place on the afternoon of Saturday, November 5. 'Love the way' wrapped VIA 6420 led the two cars - Chateau Richelieu and coach 8138. The train arrived in Ottawa's Walkley Yard around 0630 today. Chateau Richelieu was one of the cars stranded in Churchill in 2017 and not reported in service since, and 8138 has not been reported in service since early-2021. On the tail-end was Chateau Laval. Operating as Extra 627 between Montreal and Ottawa, the unit and Chateau Laval were observed on an east-side stub-end track at Ottawa Union Station the day after. It's interesting that the Montreal-Ottawa movement was made at night, similar to some of the early Siemens trainset testing!

Cue the railfan rumour mill/conspiracy theorists, "What the **** is VIA hiding?!", asked one.) Well, interestingly, it turns out the AEI car reader tags from the two cars had also been removed. Though the locomotive and trailing car registered on CN's AEI reader at Coteau at 0438 on November 6, the wrapped cars did not - only that two four-axle cars were mid-train. (Though tarped, the tarps would not impede the radio signals.) There are no AEI readers between Coteau and Ottawa, nor between Ottawa and Brockville, so there is no record of these movements in and out of Walkley Yard.

NOVEMBER 8 UPDATE: Two baggage cars and a diner are expected to travel from Montreal to Ottawa on the 9th for subsequent NRC testing.

NOVEMBER 10 UPDATE: Gilles Gagne' of Le Soleil news network in Quebec has just published this this investigative article. In it, Gilles lists the detailed questions has asked of VIA Rail, for which he received no answer. Gilles also reports [translation from French] the discovery of a crack of a few centimeters very close to the trucks, the assembly including the wheels, at a place where the stainless steel was welded to the steel atop the upper part of the trucks.

DECEMBER 20 UPDATE: Inquiries to the National Research Council regarding VIA car names/numbers undergoing testing elicited this response: "Thank you for your interest, but due to a non-disclosure agreement, which is commonplace with our clients, the NRC is not in a position to share details about the research. The details of the research and testing are the property of the client. For more information, please contact VIA Rail directly." An inquiry to VIA Rail, already keeping the lid tightly closed on the informational cookie-jar, would likely result in a similar NDA-centred response. An email inquiring about the Access To Information request process was replied to by a VIA Legal Affairs paralegal - fifteen days after it was sent.

DECEMBER 27 UPDATE #1: A coach in the 'D&H' scheme, a Chateau (possibly Ch. Roberval?) as well as 8517, Strathcona Park and Waterton Park were noted at CAD by Mark Charlebois today. (Waterton Park had sat at VIA's MMC since at least October, 2022.) Mark kindly shared these outside-the-fence photos:

Other cars previously noted at CAD and/or part of the NRC testing 'rumour mill':

- Strathcona Park with only emergency, dome and bathroom windows. Moved from VIA's MMC, where it had been since spring 2020, (as was Revelstoke Park, also at MMC), to CAD. Strathcona Park disappeared from public view in early January!

- Business Class car 4006 in the (grey) "D&H" scheme, on the same track as Strathcona Park.

- Coach 8126, though has been in Corridor service October to December/22

DECEMBER 27 UPDATE #2: It is now expected that no further cars are to be tested, only VIA 8138 and Chateau Richelieu. This is based on the Transport Canada order for VIA to conduct a static compression test of at least two unrepaired HEP cars. Or to put it another way, two.

JANUARY 6 UPDATE: A reply concerning early testing reults, from an anonymous industry source, as posted to social media:

JANUARY 15/23 UPDATE: An RDC-2 took the place of Strathcona Park in the CAD yard, with 8517 and Waterton Park still visible.

JANUARY 27 UPDATE: Following the Access To Information request I submitted to VIA Rail, this response was provided: "VIA Rail train cars #8222 and #8138 were prepared and shipped to the National ResearchCouncil on November 6, 2022." Although I continue to hear rumours and opinions that more cars are to be tested, I'm satisfied with this response. This process worked well if not quickly, and I will submit another request upon the emergence of concrete proof of additional cars being sent for testing. The request was subsequently posted to VIA's 2023 Completed Access to Information Requests webpage:

Also on January 27, and just four short days before the mandatory Transport Canada reporting date of the structural testing, VIA released a Notice of Market Consultation, stating in part, "VIA Rail intends to renew its existing long distance regional and remote fleet by selecting a supplier to design, manufacture, test, supply, deliver and commission cars and motive power and ancillary equipment (on-board and offboard) with a prescribed capacity of car types (seated coaches, sleeper, diners, multi-purpose, baggage) through an open competitive procurement process (the “Long Distance Regional and Remote Fleet Renewal Project”).

VIA Rail will proceed with pre-procurement activities regarding its Long Distance Regional and Remote Fleet Renewal Project. As part of these pre-procurement activities, VIA Rail intends to engage in consultations with motive power and rolling stock manufacturers to solicit feedback on VIA Rail’s proposed technical specifications, maintenance’s scope of work as well as commercial & contractual related terms."

FEBRUARY 9 UPDATE: In a TRAINS magazine blog post from aboard VIA No 2 in BC, Bill Stephens shared this, still mentioning four cars(!): Right now four of the venerable Budd cars are being sacrificed in Montreal. They’re being stripped to their frames and undergoing detailed inspections and metallurgical analysis. Then they’ll be put through destructive stress testing that will simulate a collision. The goal is to determine if they’ll buckle at the vestibules, as designed, or in their interiors, as feared.

In a few weeks we should know the diagnosis and the prognosis. (An initial report on the test findings was due on Jan. 31. VIA Rail representatives did not immediately respond to an email seeking an update today.) The best case would be that the cars sail through the testing or can get by with frame modifications. The worst case would be that there’s no fix and the cars are deemed so unsafe that they must be pulled from service. That would be the Canadian’s death knell.

- Business Class 4006

- Diner Alexandra (photographed Feb.12)

- RDC-2 6208

- Chateau Rouville

- Stuart Manor

- Graffiti-covered Baggage 8618

- Skyline 8505

- Strathcona Park and Waterton Park were not evident, though Waterton Park had already been delivered to NRC above.

NOVEMBER 17 UPDATE: Efram Ellenbogen took this photo while passing CAD showing the torn-down cars still there (from left - Alexandra-6208-4006-Chateau Rouville-Stuart Manor-8618-8505-Strathcona Park). Thanks, Efram!

NOVEMBER 17 UPDATE: Efram Ellenbogen took this photo while passing CAD showing the torn-down cars still there (from left - Alexandra-6208-4006-Chateau Rouville-Stuart Manor-8618-8505-Strathcona Park). Thanks, Efram!I'm publishing this post on November 7, which some have termed National Railway Day. On this date, 137 years ago the CPR was completed with the driving of the Last Spike at Craigellachie, BC. Those builders and pioneers could scarcely have imagined the changes brought to Canada's railways since!

Top photo - screen capture showing VIA Extra 627 at Walkley Yard, from Twitter video posted by @MattPinder1 Beyond the Automobile

.JPG)

.JPG)

.JPG)