This

previously-published post on the CN-imposed speed reductions on VIA Siemens Venture trains in the Corridor was published on October 12, 2024. The day before that, VIA was informed by CN that there may be safety issues due to its Siemens Venture trains not shunting properly. My learning curve of shunt-related issues instantly became very steep. Would CN deal with the safety issues and VIA operations quickly?

In the meantime, I had been busy adding more and more information on all things shunt, as well as updating the post with VIA/CN operational changes, news accounts and other information that came to light. It got too big and too specialized to remain whole. Now, this enhanced post contains just the technical information, leaving the initial post to deal purely with the CN/VIA issues. This post includes some of the text and photos excised from the initial post, along with much newly-discovered background technical information.

WHAT IS SHUNT, ANYWAY?

Shunt is basically the act of a locomotive and or rail car completing (shunting) the circuit in a section of signaled track to show occupancy. Signal systems are divided into blocks or varying lengths, depending on the territory. When there is no train in a block, the block will show as "clear". When a train enters the block, the wheels and axles bridge the "gap" between the two rails, completing the circuit and showing that the block is occupied. The act of the wheels and axles completing the circuit is called shunting, the result simply SHUNT.

Within a track circuit, there is electrical energy from a low-voltage battery connected through a current-limiting resistor to a track relay, completed through a track's two rails. Current flows from the positive terminal of the battery down one rail, through the relay and back through the other rail to the battery's negative terminal. Once energized, the relay contact closes, indicating that the track is occupied. As a train moves through the track circuit, wheels and axles provide a lower-resistance electrical path for current to flow, known as SHUNT. Shunt short-circuits the track, taking current from the relay and causing the relay contact to open, indicating the train is present. Once the last car of a train leaves the circuit, the relay again becomes activated, allowing crossing flashers to go off and the gates to return to their upright position thereby permitting highway traffic to cross.

A reliable wheel-to-rail connection is essential to provide a path for shunt. Shunt quality between rail and wheels should be zero ohms. In reality, the rail-wheel interface is affected by factors degrading shunt quality i.e. light equipment weight. The US Federal Railroad Administration (FRA) mandates a low baseline of 0.06 ohms that must be detectable by the track.

WHY IS SHUNT IMPORTANT?

Well, if a train loses shunt or shunts intermittently, that can create lots of problems for the signaling system! Trackside signals, crossing protection, wayside train detection, really every warning device relies on block occupancy and shunt to function properly.

Poor shunting occurs when a significant amount of track current is lost/leaked under the axles, causing a receiver to register a false unoccupied track circuit. The result is signalling to motorists and/or pedestrians that it is safe to cross a track when it is not.

Grade crossing warning devices should give at least 20 seconds of warning of an approaching train. While loss-of-shunt may not result in a total activation failure of crossing protection, it may result in shortened warning times during which the crossing signal system is operating and giving the desired protection.

Poor shunting is also the reason railroads usually limit single light engine moves to 30 mph or less, as a single locomotive moving faster than that can run the risk of losing shunt. This has happened with single locomotives running light in an approach-lit signal block. The locomotive lost shunt and the signal actually shut off for a few seconds before flicking back on!

WHAT IS LOSS-OF-SHUNT?

Loss-of-shunt is described as a brief deactivation of flashers or gate arms while passing trains are still occupying highway grade crossings. A temporary loss-of-shunt (which may cause a deactivation) in grade crossing warning devices while the train spans the crossing, may create a question of reliability in the minds of individuals dependent on them.

WHY IS LOSS-OF-SHUNT ESPECIALLY IMPORTANT FOR PASSENGER TRAINS?

There are many pundits and online 'experts' asking questions like, "Why is there a problem? We had RDCs for years! This is all just made up! VIA has been running Venture trains for two years!" But once the following factors are taken into account, and taken seriously, the potential for loss-of-shunt and accompanying danger at crossings become very real possibilities.

Short passenger trains, consisting of fewer than 32 axles, have a history of poor shunting. Passenger equipment is, on average, much lighter than freight equipment, and can lose shunt more easily. This is why railroads like CN and CSX have imposed minimum axle counts in passenger trains (usually 20 axles or more), because there were issues with passenger trains failing to shunt trackside signals and/or crossing protection. My mind keeps going back to this photo posted to social media of a Venture set running west of Toronto early in September. The one and only time I've seen a 32 axle-count train operated by VIA. Is it any coincidence that speed reductions on the 24-axle Venture trainsets were implemented by CN one month later? What did the operation of this test train reveal?

Loss-of-shunt affects lighter passenger equipment, like Venture-equipped trains, moreso than freight equipment, or even VIA's Legacy passenger equipment. Why? Passenger equipment is maintained and inspected to a higher standard compared to freight equipment, especially when it comes to wheels and ride quality. Passenger equipment wheel profiles are maintained to a much stricter standard on passenger equipment to provide superior ride quality. In doing this, it moves the wheel to rail contact patch higher up onto the rail head, out of the wider back-and-forth slog patch of freight wheels. The tops of rail are hardened, and as such are much harder to keep clear of contaminants, due in part to the tendency of head-hardened rail to crack microscopically. Over time the passage of a few short passenger trains of a lighter weight are not enough to polish the hardened rail heads, and keep them free of contaminant.

Therefore, the four root causes of loss-of-shunt for passenger trains are:

- Equipment with consistently-trued wheel profiles

- Trains with fewer axles i.e. <24 axles

- Light equipment weight i.e. <400 trailing tons

- Head-hardened rail

To give an idea of the comparative weights of various types of passenger and freight equipment:

- Loaded freight car - 315,000 lbs.

- Passenger locomotive - 280,000 lbs.

- RDC - 118,000 lbs.

- Siemens Venture car - 112,000 lbs.

- Empty freight car - 60,000 lbs.

From July, 2002 to August, 2010 there were 57 activation failures, without explanation, involving Amtrak trains on CN. At least one train was 'lost' on a dispatcher's panel for 15 seconds! There were three more such incidents in 2014-15, resulting in crossing warning times of 13-19 seconds.

John Black, a member of the Loss-of-Shunt Technical Committee, reached out to Trackside Treasure with additional information. The National Loss-of-Shunt Committee comprised representatives from CN, BNSF, Caltrans, Amtrak, UP, Illinois DOT, FRA, Alstom, ICC, Siemens, NS, CSX and Metra.

John sent a link to this earlier FRA

1993 report [spoiler - dullness warning, according to John!] On November 8,1990, the Operations General Committee of the AAR requested that the AAR Research and Test Department conduct a test and evaluation project determining the causes of loss-of-shunt on track circuits. The report describes work results and recommends future direction for FRA-funded efforts, also describing AAR/Committee-funded efforts. Interestingly, one of the loss-of-shunt data-collection test sites was here on CN's Kingston Subdivision, near Brook Road in Cobourg. Even though the sites were chosen by the railroads because of their history of poor shunting performance, the overall level of occurrence at these sites was low. As of May 1, 1993 data collected on over 10,000 trains showed only 46 trains exhibiting loss-of-shunt, an occurrence level of less than 0.46 percent.

This is where the investigations were started, but they really didn't pick up any co-ordinated effort until a Detroit-Chicago Amtrak train operating on CN tracks in Michigan's Canton-Township hit a vehicle and killed the five occupants on July 9, 2009. There had been several documented reports of activation failures at this one crossing with no apparent equipment malfunction found. The US Federal Regulator found CN at fault, which was the start of mandated minimum-axle counts, and CN was directed to lead an industry-wide task force to find mitigations for the loss of shunt issue.

Following CN's lead, other railroads initiated minimum-axle counts for passenger trains on certain subdivisions. This has impacted certain regional trains, which are now mostly funded by the States. Sometimes the only available cars are dissimilar, heavier cars like Amtrak Superliners. Having to lug around an unoccupied, heavy car adds a significant cost to the operations that may be already struggling to regain ridership post-pandemic.

LOSS-OF-SHUNT TESTING - AMTRAK & CN

In mid-August, 2023 the latest instalment of an ongoing series of tests was staged out of Canadian National’s Effingham yard in southern Illinois. The sessions, attempting to seek a permanent solution for locations where loss-of-shunt issues are ongoing, were attended by participants from CN, Amtrak, FRA, the Illinois and California transportation departments, and equipment vendors. The effort was led by CN. These were certainly not the first loss-of-shunt tests, nor were they the last. A summary of testing on CN's Champaign Subdivision included:

- 2018 Brake Shoe testing (disk, tread)

- 2019 Wheel Profile testing (varying wheel profiles)

- 2019 Rail Brush testing (cleaning of railhead contaminants)

- 2021 Siemens Venture rail car testing

- 2022 Rail [pickup] Shoe testing

- 2022-23 Onboard Shunt Enhancer (OSE) testing (mounted on locomotives and hi-rail trucks)

- 2024 OSE testing on a live 16-axle consist.

CN asserted that extensive testing had indicated that the random loss-of-shunt detection events experienced by single-level passenger equipment [on CN lines] in the US was due to the absence of sufficient contact area between the wheels of passenger trains and the railhead. CN's contention was that the smaller contact area on the wheel profile of passenger equipment, combined with short and light trains, was preventing the systematic sufficient transmission of current necessary to activate fully operational and FRA compliant railway crossings.

Addressing why Superliners were required on the Illini-Saluki route, CN asserted, “Due to the safety concerns, CN required either the use of heavier equipment or lowering the maximum operating speed at grade crossings for single-level equipment on this route. This was the responsible thing to do to ensure safe operations.” The speed restriction did not apply with Superliners, which were found to consistently shunt the circuit. Another CN contention was that it was false to claim it only happens on some routes, as any route with these aspects present would likely result in random loss-of-shunt events. (These claims and potential causes of widespread loss-of-shunt may have been a key justification for CN's speed-reductions at grade crossings for VIA trains.)

John kindly shared two photos of the second-round February, 2023 testing on CN with Amtrak California F59PHI 2007, in Pontiac MI. CN set up a short track [Loss-Of-Shunt Test Track] on which controlled tests could be run with all manufacturers' Grade Crossing Predictors. Both Siemens and Alstom also sent their representatives to work with CN for this testing, as well as the mainline testing in Michigan and Illinois. [Thank you, John!]

SHUNT AND SIGNALS - A RETROSPECTIVE

How can this still be a problem after all the trains operating on many railroads for decades, including lightweight RDC's, Turbo trains, and other trains with single-level equipment? Going way back to the days of the RDCs, loss-of-shunt was a problem with both grade crossings and CTC circuits. Crossing gates must work 100% of the time. If I'm driving over a level crossing, even 99.5% is not good enough! Who can forget VIA's operational challenges during the

ADtranz Flexliner demonstration period in 1996-97? There were early technical problems - signals not being activated due to the cars' light weight. Flexliner trainsets could apparently 'disappear' from dispatcher's computer displays. This led to an immediate withdrawal of the Flexliners from service, mandated by Transport Canada. The trains were withdrawn beginning September 30, 1996, just one day after the Flexliner temporary service had begun! The withdrawal lasted nearly two months. The units were stored until further testing took place in early October. Composite brake shoes were replaced by steel brake shoes as a remedy.

VIA's Siemens Venture trains have tread brake shoes as well as disc brakes. Though Charger locomotives only have disc brakes, they are also equipped with a Knorr Block tread scrubber, which is not visible and largely unknown except to maintenance crews. It's a small brake shoe that is pushed against the wheel to keep the tread clean. It is controlled by the software and comes on/off automatically during AB applications. It's very effective at keeping the tread clean, and without it there is none of the cleaning of locomotive wheel treads that tread brakes provide.

The evolution of grade crossing warning devices started with old-style AC/DC crossing circuits with insulated joints that acted as an on/off switch. The train hit the circuit and turned on the protection. The circuit was of a fixed length, equipped with simple relays. The insulated joints were marked out to the distance of the fastest moving train speed which set the minimum warning time of about 30 seconds. So an 80 mph passenger train would have a 30 second warning and a slow crawling freight would have a far longer gate-down or flasher-on time, which often encouraged motorists to go around the gates or run the crossing.

Sensors are electronic circuitry that are more advanced than the AC/DC, and sense a train when it hits the circuit controlled by shunts.

Grade Crossing Predictors (GCPs) evolved from the 1970s, in order to take into account varying train speeds and keeping gate and flasher times consistent so that an 80 mph train and a 20 mph train will have the same warning times. They are more sensitive than sensors and if there are problems then they can be switched to sensor mode only, but that then gives shorter warning time for fast trains and longer warning time for slow trains. This is a common occurrence if conditions are such that the predictor mode has to be turned off due to false activations. Turning the current up makes the crossing more sensitive, but also increases the likelihood of a false activation, causing more issues.

GCPs monitor the rate of change in track impedance as a train approachines the crossing. The rate of change detects motion and predicts the time of train arrival at the crossing. Long freight trains may not activate the crossing as soon as those travelling at the maximum speed on a given stretch of track. For instance, a detection point 3,500 feet from the crossing gives 40 seconds' warning time for a freight train, only 30 seconds for a passenger train.

Developments in programmable logic control of wayside track circuits have enabled direct control of signal lamps by vital logic controllers. Siemens' GCP 3000 takes a reading every second, and has three five-second periods during which it can detect approaching trains travelling 60 mph, but only one five-second period during which a 78-mph passenger train can be detected. That is because if the first axles do not shunt well, the predictor may jump to another axle farther back in the train, making the train appear slower or give shorter warning times.

As early as 2009, CN employed upgraded software to Siemens GCP 3000s and installed crossing event log-recorders along its Chicago-Carbondale corridor, also instituting a minimum 30-axle requirement. CN could add loss-of-shunt timers or enable loss-of-shunt programming in the predictors. These features have been built into most predictors since the year 2000.

I am not aware of whether there are specific crossings on CN's trackage used by VIA in the Corridor that have problematic technology. Clearly, CN has identified such specific crossings over which Venture trains must ensure operation of crossing signals for 20 seconds, reducing their speed from 80+ mph to 45 mph. Rather than replace or upgrade potentially problematic grade crossing protection at their cost, CN will likely favour VIA preventing loss-of-shunt by paying to install shunt-enhancers on their Venture trainsets.

ON-BOARD SHUNT ENHANCERS (OSE)

Siemens makes crossing signal safety products. Perhaps VIA's Venture sets will have to be equipped with Siemens

shunt-enhancers. On-board shunt-enhancers were first developed in the United Kingdom in the 1980s for use with Diesel Multiple Units (DMUs) that did not have locomotives pulling them. OSEs are coils or antennae above each rail which induce an electromagnetic field that pushes more current through the wheels and axles, thereby overcoming contact issues and helping along the track circuit current. FRA regulations only permit flexible non-metallic sand pipe extension tips and trip cock arms to extend that close to the railhead. The shunt-enhancer antenna, which injects a 2- to 4-amp, 165-kHz signal into each rail to amplify current for a circuit that activates signals and highway warning devices, would be installed above the 2.5-inch threshold. But other factors like worn wheels and dynamic profiles might cause the device to protrude lower, hence the need for a FRA waiver.

Reiterating the four root causes of loss-of-shunt for passenger trains:

- Equipment with consistently trued wheel profiles

- Trains with fewer axles i.e. <24 axles

- Light equipment weight i.e. <400 trailing tons

- Head-hardened rail

It is apparent that since none of those root causes can be changed, loss-of-shunt must be mitigated. OSE's are the most practical method, from both reliability and maintenance standpoints.

MITIGATING LOSS-OF-SHUNT

The major contributing factors to loss-of-shunt include: rail-to-wheel interface, equipment dynamics, crossing equipment, contamination, environmental factors and operational factors. Here are three of the most critical to loss-of-shunt:

1. Rail-to-wheel interface

Passenger equipment's car-to-car variance is minimal because passenger railways like Amtrak and VIA maintain tight tolerance of wheel profiles and regular inspections per preventative maintenance protocols. Passenger wheels have a 1:40 wheel taper at the wheel tread, therefore a small contact patch on the rail. Freight wheels have a 1:20 wheel taper at the tread, therefore a larger contact patch on the rail. Passenger contact band on rail is usually 1" at the centre of the railhead. Variable freight car wheels result in a 1.5-2" contact band on rail, covering two-thirds of the railhead. When resistance values are measured across the railhead, passenger cars trend more to the centre-to-field side of the railhead with higher resistance values therefore more difficulty shunting, compared to the wide contact band of freight car wheels across the railhead.

2. Equipment dynamics

Lighter passenger equipment - with light axle loads and narrow tread profiles - have a smaller rail contact area, increasing impedance between wheel and rail, resulting in poor shunting. Real-time wheel loading and unloading varies due to the pronounced movement compared to the same wheel load of the same equipment while at rest. There is a higher chance of wheel unloading at higher speeds, i.e. 78 mph compared to 60 mph, and on lighter equipment, and on trackage where poor shunt is pre-existing. Good shunting requires reliable wheel contact of both wheels on the same axle.

3. Contamination

Various reports from North American, European, and Japanese railroads have identified the principal cause of loss of shunt as "semi-conductor oxide film," composed of rust, black iron oxide (magnetite) or other foreign particles from brake shoes. Films composed of leaves, and lading materials also have caused loss of shunt, usually on rare, site-specific instances. Contaminants that may exist on or around the railhead include rail lubricants, leaking oils from freight cars, sand from locomotives, rust on the railhead, vegetation next to track and non-conforming brake shoes. The cause of the loss-of-shunt may be from such contaminant semi-conductor films on both the wheel and rail. These films may be thicker in some locations than others, and may be exacerbated by variations in wheel/rail profile.

AMTRAK APPROVES SHUNT ENHANCER FUNDING

In a September, 2024

letter, the FRA conditionally approved Amtrak’s waiver request applied-for on August 25, 2023 allowing installation of shunt enhancing antennae in a decision letter. The conditions are significant, requiring further testing, procedural changes and documentation before using the antennae in revenue service. Amtrak requested a waiver from 49 CFR § 229.71, Clearance above top of rail, to implement the locomotive-mounted Track Circuit Assister Shunt Enhancer (TCA SE). Section 229.71 states that no part or appliance of a locomotive (excepting “the wheels, flexible non-metallic sand pipe extension tips, and trip cock arms”) may be within 2.5 inches from the top of rail. Amtrak seeks to install the shunt enhancer on its fleet of Siemens Charger SF4 locomotives. Amtrak explained that under conditions of worn wheels and dynamic profiles, the mechanical and electrical hardware of the TCA SE could protrude below 2.5 inches from the top of rail. (VIA has previously removed the sand pipes from its 900-series P42 fleet and its 6400-series F40 fleet.)

FRA’s field investigation included a visit to Amtrak’s facilities and interviews with Amtrak staff. Interviews confirmed that potentially, the TCA SE can get as low as 1.19 inches, with the current design showing 1.21 inches ATR. The TCA SE is made of 3 millimeters of thin copper coated tubing that injects a signal into the rail. The tubing is aligned between the lead and trailing wheelsets of the truck and is protected from physical damage, as it is not extending beyond the plane of the wheel on either side. FRA technical staff concluded that the TCA SE is adequately protected from potential physical damage. When properly installed and the alignment inspected during calendar day inspections, there is no risk of antenna interference with the wheel/rail interface. In the case of damage due to a foreign object or track structure component impact, the TCA SE tubing will potentially deform and deviation of its designed geometry will trigger fault indication on the control box. In the event of a break of the tubing, the loss of signal from the drive box under each truck to shunt assist boxes in the engine room will de-energize the antenna.

The Board determined that granting Amtrak’s request is in the public interest and consistent with railroad safety. Accordingly, the Board grants the waiver from § 229.71, subject to the following conditions:

1. Amtrak must finish failure and risk analysis of the design (PFMCA), review the PFMCA with FRA’s Office of Railroad Safety, and implement any mitigation measures prior to installation of the TCA SE on the Siemens Charger SF4 locomotive fleet.

2. ATR clearance must not be less than 1.19 inches at any time.

3. The following requirements must be added to Amtrak’s inspection requirements for the Siemens Charger SF4 locomotive fleet:

a. TCA SE system test, components, and securement elements to the periodic inspection work scope.

b. TCA SE visual inspection to the mechanical calendar day inspection requirements.

c. TCA SE health indicator light functionality to the mechanical calendar day inspection requirements.

4. Testing of the TCA SE on the Siemens Charger SF 4 on mainline track must be performed with adequate safety protection, including speed restrictions and absolute block protection, until it is confirmed that the TCA SE does not interfere with the governing signaling system and equipped highway-rail grade crossings on the test route(s).

5. Amtrak must submit a report to FRA and the public docket for this waiver that verifies and validates the improvement in shunting performance realized through installation of the TCA SE on the Siemens Charger SF 4 locomotive, including supporting data and test results.

6. Amtrak must submit a report to FRA 30 days prior to commencement of revenue service of an equipped TCA SE Siemens Charger SF 4 locomotive that documents the results of signal and grade crossing interference testing on each route that a TCA SE-equipped Siemens Charger SF 4 locomotive operates, confirming no interference with the normal functioning of the signal and grade crossing systems. Simultaneous with submission to FRA, Amtrak must also upload the report to the public docket for this waiver.

7. Amtrak must demonstrate the overall hardware and software system safety of the TCA SE equipped Siemens Charger SF 4 locomotive in accordance with Amtrak’s hardware and software safety program1 and make the results available to FRA upon request.

8. Amtrak must initiate a formalized reporting procedure for employees witnessing or experiencing a LOS event following installation of the equipment, conduct a detailed analysis following any LOS incident, and report the findings to FRA’s Signal, Train Control and Crossing Division.

9. For any other classes of power on which Amtrak intends to install the TCA SE, Amtrak must first obtain FRA approval for the installation.

FRA funding for shunt-enhancers was announced in late-October. The FRA’s Consolidated Rail Infrastructure and Safety Improvements (CRISI) granted $58.8 million to Amtrak to install Onboard Shunt Enhancement devices on 443 locomotives and 192 cab cars to prevent trains from losing shunt, which can cause problems with signal and crossing-gate activation, part of a $2.4B announcement. By my math, $93,000 US per installation. Maybe less if some of that is program costs or other budget wizardry. The funding award is a separate process that does not imply that Amtrak has fulfilled the conditions enabling use of the antennas in revenue service.

JULY 2025 Update: The new US administration has frozen CRISI grants for review. Some have been un-frozen, though the shunt-enhancers was not included.

Park Engineering, part of UniPart, isometric diagrams (below) showing OSE installation on Siemens SF4 ALC-42 locomotive trucks. Park Engineering has also produced similar systems for British Rail, some in service for five decades!

Excerpt from a letter from Amtrak's Director of Equipment Engineering - Locomotives to the FRA re: the waiver request;

HOW WILL CN AND VIA SOLVE THIS PROBLEM?

It remains to be seen whether Canadian railways like CN and VIA will follow Amtrak's lead and implement OSEs, or attempt to continue speed reductions or other measures to mitigate the loss-of-shunt issues that apparently persist. We know that VIA and CN are both named in a judicial review currently at the Federal court level.

If OSE implementation were to go forward, this would involve testing, regulatory approval and a stepwise implementation process. Any list of standardized protocols for the implementation of OSEs on passenger trains will have to include several key recommendations. Such trains would be light weight consists in passenger and commuter service of less than 400 trailing tons and 32 axles. Antennae would have to be mounted on both the A and B trucks of the leading equipment. Antennae would be of a proper shape for specific truck types, both trucks' OSEs functioning together in parallel with the rail, and centred over the rail. Locomotive engineers would need a visible fault indicator if the antennae or system became faulty. There would have to be inspection at least semi-annually, with records kept.

If OSEs become the gold standard for preventing loss-of-shunt incidents, railways may actually prevent passenger train operators from operating non-OSE equipped equipment on their networks.

Not only is Siemens unhappy with CN's speed reductions on VIA, they haven't even started designing an OSE for Venture cab car use yet!

In an upcoming post, I hope to present more detail on the justification that CN presented to VIA for its speed reductions at crossings on VIA's Ventures, through the courts and/or through access-to-information legislation.

November 19 UPDATE: In response to my Access to Information request, VIA replied that since an application for judicial review before the Federal Court has been filed on November 12, 2024 [a mere week before their response to me, and nearly three weeks after my request dated October 23], they were unable to fulfil my request citing protection of the requested information under specific stated sections of the legislation. While that was somewhat disappointing, I was provided with VIA Rail’s judicial review application before the Federal Court tabled on November 12, 2024. More on

that ponderous judicial process in this post!

The saga continues...

MEANWHILE....SPOTTED IN RICHMOND, ON

VIA already has this Fabri-Tek Motorized Rail Brush trailer with hi-rail wheels sitting in the parking lot of the PNR/VIA (formerly Siemens/CN) tollhouse in Richmond, ON. (Above - posted to social media.) It's equipped with wire wheels to clear leaves and rust from railheads to increase conductivity and improve shunt, thereby ensuring that crossing gates go down at the proper times.

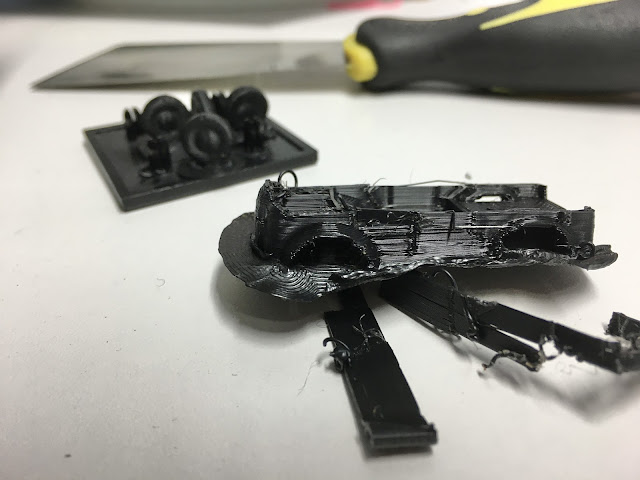

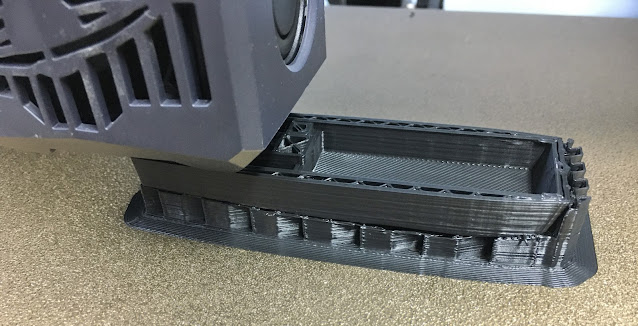

The trailer was designed and built for VIA to keep track circuits working due to not a lot of heavy traffic operating on its trackage. Inventor Zach Chenier, a former signal maintainer with CN and RailTerm, operates Farbi-Tek Creations in Alexandria, ON and noted that this trailer is designed to prevent short crossing warning times in ABC [sic], or CTC circuits, regardless of whether track circuits employ GCPs, MicroLok or HXP technology. (Below - Fabri-Tek photos)

It's reportedly easily taken off at railway crossings by one person so it’s far from rail-bound, making it easy to complete work under traffic with minimal resources. The unit is towed behind a hi-rail truck in the Ottawa area at least monthly. They are also used on the Glencoe-Windsor Chatham Sub that reportedly sees eight VIA movements and two CN freight movements daily. Hmmmmm......